Safety & Life Courses

Nutech Phoenix is an accredited and certified group in fire, life and safety, for both occupational and public safety, that comprises of unique integrated training, education, products and services available across BC. We offer the majority of the courses in our Richmond and Kamloops Training Centers. Our three divisions, FIRE, LIFE and SAFETY, provide a wide-range of training courses to ensure your business and employees are trained and certified.

Book Your Course Today!

We are now running fall protection/arrest courses in the Kamloops Location Only. Date for upcoming fall arrest course is May 17th. Maximum 10 people per session. Call the Kamloops office to book at 250.828.2888.

Explore Our Courses

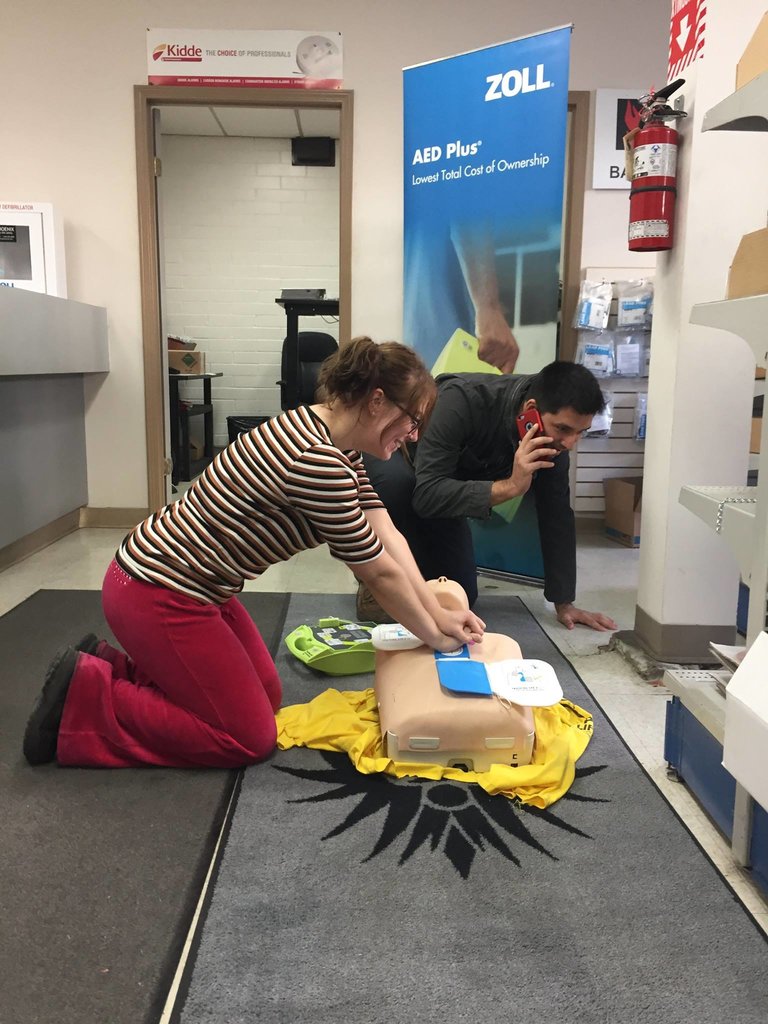

The WorkSafeBC Occupational First Aid Level One course is an 8-hour program, including coffee and lunch breaks. In order to be successful, candidates must demonstrate practical skill competency and achieve 70% on a multiple choice exam. Upon successful completion of the course, participants receive a 2-year certification.

The course curriculum includes: Basic Life Support (CPR-A), Small Wound Management, Critical airway, breathing and circulation interventions with C-spine management.

What You'll Learn

- Cuts

- Broken bones

- Burns

- CPR

- Personal protective equipment

- Automated external defibrillators

- Workplace administrative requirements for first aid attendants

- Legal implications of first aid and CPR

- Small wound management

- Critical airway

- Breathing and circulation interventions with C-spine management

The WorkSafeBC Occupational First Aid Level Two course is a 36 hour program designed for the urban attendant. Initial certification requires full participation and course attendance, as well as satisfactory results in both a written and practical exam. Upon successful completion, the participant will receive certification that is valid for 2 years.

The course curriculum includes: Basic Life Support (CPR-A), Scene assessment, Patient assessment

- Critical airway & breathing and circulatory interventions with C-spine management; including insertion of oral airways, use of oxygen therapy equipment and bag valve mask

- Small wound, soft tissue, and fracture management

Here is what you will learn when you take the Occupational First Aid Level 2 course at Phoenix Fire Prevention:

- First Aid Skills: When you complete this course, you will be equipped with the skills to perform the priority action approach when a medical emergency occurs.

- Identify Circulatory Emergencies: You will be able to identify circulatory emergencies and manage critical interventions for people are either conscious or have a decreased level of consciousness.

- Manage Critical Interventions: Learn how to use C-spine control so that you can help somebody breath more easily without hurting their spine.

- Assess Medical Conditions: You will learn how to manage, identify and assess when somebody is in need of medical aid for soft tissue injuries.

- Identifying Respiratory Emergencies: You will learn how to identify and manage respiratory emergencies.

- Conduct Secondary Survey Components: You will learn how to conduct the secondary survey component of the priority action approach.

The WorkSafeBC Occupational First Aid Level Three course is a 70 hour program designed for remote work sites or employers with large workforces more than 20 minutes from medical aid. Initial certification requires full participation and course attendance plus passing both a written and practical exam. Upon successful completion, the participant will receive certification that is valid for 2 years.

The course curriculum includes:, Basic Life Support & CPR (CPR A), Patient assessment, Critical airway & respiratory, interventions with C-Spine management, including insertion of oral airways, use of oxygen therapy equipment and bag valve mask, Circulatory interventions and management, Small wound, soft tissue, and fracture management, Rapid transport criteria, Suction.

Here is what you will learn about and practice during your time in the Occupational First Aid Level 3 course offered at Phoenix Fire Prevention:

- Basic life support and CPR

- Critical airway and respiratory

- Patient assessment

- Use of oxygen therapy equipment and bag valve mask

- Interventions with C-spine management (including insertion of oral airways)

- Circulatory interventions and management

- Small wound, soft tissue, and fracture management

- Rapid transport criteria

- Suction

At the end of the 2 week program, you will be required to write an exam and achieve a 70% in order to receive your certificate. The certificate is valid for two years.

This course focuses on the obligations of when and what type of fall protection to utilize. It covers the hierarchy of selection and how to make that informed selection. It includes the thorough inspection and fitting procedures for the equipment. Every component is described in its composition and limitations and use. The course is equipped to get you comprehension from the basic questions of use and care to training and rescue.

The practical component will see that you obtain proficiency in selecting, inspecting, fitting, caring, using and storing the equipment. It will cover standards and criteria for rejecting equipment.

This course is a two-day course for beginners and one-day for advanced operators. The following is a breakdown of the four sections of the course:

Phase 1 – Theory Training

During Phase 1 the instructor guides trainees through a comprehensive and interactive review of the operator workbook covering: Applicable Regulations, Types of Forklifts, Main parts of a Forklift

- Understanding Forklift Safety, Fuels and Batteries

Phase 2 – Theory Evaluation

Phase 2 starts with a written test based on the concepts covered in the operators reference manuals. The test consists of ten (10) multiple choice/essay type questions. These tests are graded and returned to the trainees and then reviewed to ensure understanding. A minimum score of 70% is required to pass this phase of the program.

Phase 3 – Practical Training

Phase 3 is hands-on portion of the program where the trainees are shown the pre-use inspection, safe operating procedures and parking/shut-down procedures and then given the opportunity to practice under the helpful eye of the program instructor.

Phase 4 – Practical Evaluation

In Phase 4 trainees are assessed as having reached a minimum skill level and are individually evaluated using a Forklift in a reasonably challenging course (site specific). Following the evaluation, trainees are de-briefed and given the opportunity to address any issues they may have regarding any phase of the program. Each successful trainee’s employer will receive official records and documents shortly after the end of the program.

This course is designed based on the requirements of the provincial regulations to establish and maintain a workplace safety committee or worker representative in the workplace. This includes when and how-to setup and sustain a committee or representative. Some other topics will include training, time set aside for members, responsibilities, workplace e standards and first aid requirements. There is no practical component to this course, however, the class will be asked to get up and do some physical walk through exercises to cultivate practice in observations. This course satisfies the requirement of committee members yearly training as per WorkSafeBC.

This course will focus on the investigation process of accidents and incidents. It covers taking the investigation and using it to prevent further similar incidents through procedures or policies. It will cover the steps to investigating as per WorkSafeBC with the timelines and responsibilities. It also covers the duty of how and when to report and how do carry out the physical inspections and investigations. There is no practical component to this course, however, the class will be asked to get up and do some physical walk through exercises to cultivate practice in observations. This course satisfies the requirement of committee members yearly training as per WorkSafeBC.

This course is focused on the required theory and practical knowledge of using a telehandler in the workplace. It covers many topics including the selection of the appropriate telehandler type and class depending on the work scope. Topics include hazards for use, work site inspections and route planning, responsibilities, sizes, types, capacities, functions, and stability. The procedures of driving with or without loads and grades or ramps is also covered. The inspection, maintenance, fueling, recharging and storing the equipment will also round out the course. Telehandlers are very similar to forklifts; however, they do have a significant difference in that the forks can be boomed forward quite a distance creating a leverage hazard when using them. In addition to the forklift information, the use and hazards of booming including stabilizers and load charts are added to this course.

The practical component includes a thorough walk around of the working area and the machine as well as the loading and unloading points of the loads. Participants will show they can inspect, record and perform all functions to a minimal degree of proficiency. They will pickup various loads and deposit them into different spots. They will also perform a forward and reverse drive test to get comfortable with the steering and driving abilities. Students will also be show understanding of how to use the stabilizers and load chart for the equipment used.

This course outlines the definition of a confined space and how to determine a work space as a confined space depending on entry and exit access, regular use of the space and possible or confirmed atmospheric conditions. Pre inspection and testing and verification is covered as well as entry conditions and precautions. Other topics cover training, hazard rating and definitions, rescue, hazardous and explosive atmospheric conditions and the permitting system.

The practical segment will require the wearing of a full body harness fitted properly. Mock entry and evacuations will be performed by all students in all of the different operations.

This course is developed to provide knowledge on the planning, selection, inspection, use, care and maintenance of different type of EWPS. Some of the things encompassed are hazards for use, work site inspections and route planning, responsibilities, sizes, types, capacities, functions, and stability. We also discuss the most common concerns of power lines clearances and safety around the swing zones. Fall protection knowledge is required and best practices will be discussed in great details.

The practical component includes a fall protection inspection and assessment prior to a thorough walk around of the working area and the machine. Participants will show they can perform all functions to a minimal degree of proficiency as well as the ability to watch all paths of travel.

This course is designed to include all cranes outside the certified crane operator course and apprenticeship. It includes overhead bridge, gantry, monorail and jib cranes. It goes into very detailed information of the classes depending on usage and frequency. Other topics include tandem and critical lifting, equipment and site inspection, capacities and capabilities, and side loading. The course also covers rigging in various components, how to inspect and when to reject rigging as well as best practices in multiple configurations.

The practical assessment of this course will require participants to inspect the work place and the crane prior to use. The controls and emergency system will be tested unloaded. They must utilize a tag line correctly as well as show observation and safe positioning in body placement for themselves and others. Lifts are required with the equipment using different style of hitches and wrapping.

This is a half day course focusing on the hazards, prevention, testing, handling and disposing of possible and confirmed products containing asbestos materials. It covers the liability of working with materials and protecting all parties involved in the scope of work including clients, visitors and the general public. Some of the topics included are cause and effect of exposure in the short and long term, responsibilities and education and training. We will also cover levels of risk and how to eliminate or control them with practices, procedures and personal protective equipment. There is no practical component to this course.